Aeration in aquaculture is becoming more and more important with the increase in stocking density and use of new age farming methods like RAS, biofloc and IPRS (or raceway system as it is often called)

One of the most common questions that aqua farmers have is “which type of blower is most suitable for diffused aeration” or what type of blower should I use for biofloc aeration.

There are many types of blowers available that one can choose from. However the choice depends on many factors like:

- The species of fish or shrimp under culture. And there is a stark difference in oxygen requirement of fish and shrimp.

- Water depth and size of pond / tank

- Type of culture – for instance conventional culture, RAS, biofloc, etc.

- Type of diffuser selected and the flow rate and pressure required for the diffuser to operate efficiently

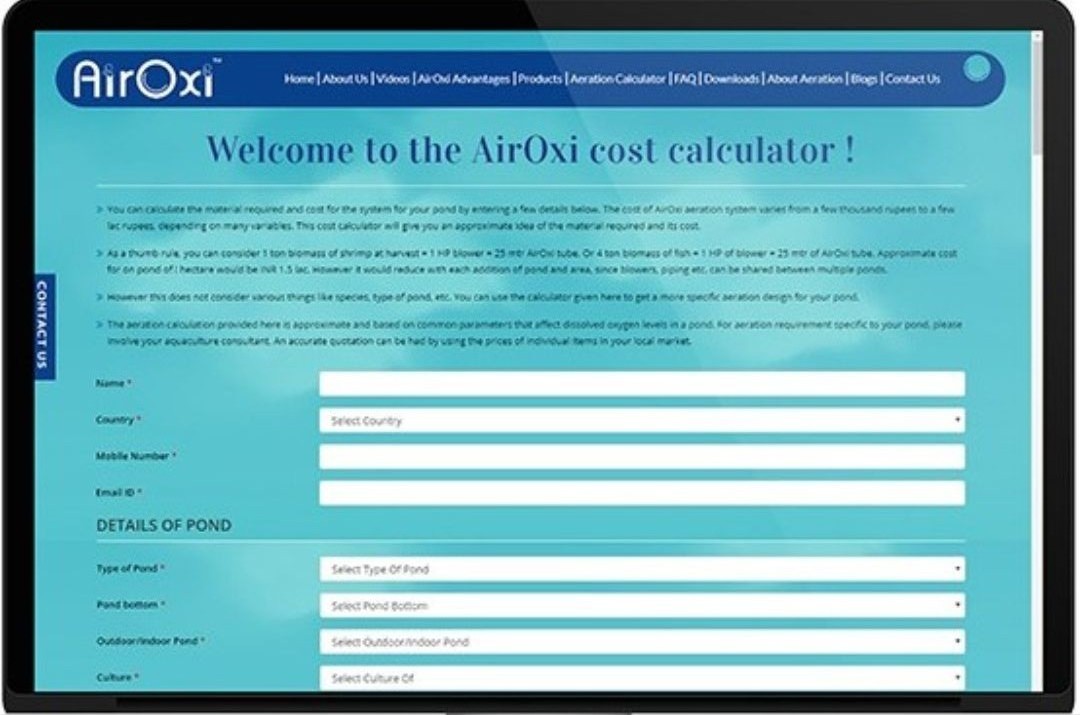

At AirOxi we have been making and testing various types of diffusers since many years. And hence we have also tested and also seen in field various blowers. So based on our experience we have tried to provide some guidance here, on which blower will be the most suitable for your culture. However as a policy we do not recommend any particular brand, and advise readers to study the technical data of available makes and models, in order to make a decision most suitable for their culture. Readers can also get in touch with us through our website www.airoxi.com or www.airoxitube.com.

There are 4 main types of blowers to select from:

1. Root blower

2. Two stage turbine blower

3. Single stage turbine blower

4. Diaphragm Air Pump

We will look at them one by one

Compressors which give high pressure and low volume of air are not suitable for aquaculture aeration. And then there are specialized devices like oxygen concentrator and DC blowers for solar application as well as for aeration in live fish transport vehicles. These are not considered here for comparison.

1. Root Blower (also called twin lobe or tri lobe blowers)

- Root blowers are designed and made for heavy industrial use like thermal power plants, cement factories, ships, effluent treatment plants, etc.

- It has a heavy cast iron body and is mounted on a frame. It is designed for long term maintenance free use.

- They have 2 or 3 lobes which created suction and push out air. Hence such blowers are also called twin lobe or tri lobe blowers.

- It is very stable, reliable and provides air and sufficient pressure against the water head of 4 to 10 feet that is common in aquaculture.

- They can be used continuously for many hours without any problem and the high pressure ensures that pressure loss due to piping is relatively less, especially over long distances. And this helps have a central place for installing blowers, rather than having to install them close to the water body.

- The technology is old and proven and there are many manufacturers of root blower in India.

- Till a few years ago they were available only in larger sizes – 5 HP and above. However recently many blower manufacturers have introduced smaller blowers of 1 to 3 HP sizes also

- The motor is separate from the blower and hence can be purchased locally with a separate warranty for it. This allows a lot of flexibility in changing the torque, RPM, etc. But if you are using this for the first time, it is best to get the motor specifications from the blower manufacturer.

- Root blowers are relatively costly and heavy so cannot be moved around, and take more space. Even the piping used needs to be heavy and takes more space.

- These blowers have a high noise level due to the construction as well as high pressure air flow.

- Tri lobe root blowers are less noisy, but more expensive than twin lobe blowers

- For aquaculture use, root blowers are usually the best type of blowers provided

- Layout of the farm is fixed and hence blowers are going to be in the same place for many months or years

- Capital is available for the higher investment required

- Relatively higher noise levels are not going to be bothersome in the neighbourhood

- Manpower is available for basic maintenance of motor, bearings, filter, mountings etc.

This is also the only blower we have found suitable for outdoor use and in large farms. All other blowers are usually designed for indoor use. It is also the blower most suitable when you have multiple ponds and tanks, thus reducing number of blowers and maintenance.

For good aeration in biofloc, we recommend 22 to 25 mtr of AirOxi aeration tube for every HP of Root blower.

2. Single stage regenerative blower (Also called ring blower or turbine blower)

- Single stage regenerative blowers, often called ring blowers, have become very popular for aquaculture use

- They are light weight and can be moved around very easily. They take up very less space and noise levels are relative low. The motors are also easy to repair locally in case of any failure.

- They usually have a 2800 rpm motor mounted with it, with a wide range of models from 0.25 HP to 10 HP and bigger, and in various motor specifications in single and three phase.

- These blowers were designed and made for light industrial use like printing or conveying powders, etc. Most of these blowers are imported since the precision aluminium die casting and the various sizes it is available in, requires high technology and capital intensive manufacturing.

- However they are available in a wide range, with suitable accessories and spare parts and can be

- Due to light weight and small size, they have many other benefits like lower cost of transportation, ease of installation, smaller size and lighter piping

- They can be installed close to the water body due these advantages.

- They are oil free and can be used for a long duration without problems or needing maintenance

- However the benefits of being light and handy, is also the cause of the poor performance of these blowers in aquaculture.

- It is designed for high air flow but at very low pressure. As a result it performs well in open condition. But with even about just 2-3 feet of water head, the RPM and thence the flow rate goes down by 50 – 60%

- It is a very light body with most of its air flow dependent on the light aluminium construction rotating very fast at 2800 rpm. As a result the slightest obstruction or increase in pressure causes the motor to heat up.

- It’s low pressure air also does not travel very far and losses due to piping are quite high

- The cast aluminium body is relative fragile and if it is damaged, then it cannot be repaired or repairs will be very costly

Hence we would suggest that the single stage turbine blower be used where the water depth is very less – 1 feet or so. For instance in hydroponics or for fingerlings or for a small culture involving only few tanks installations in a larger setup. For larger setups, this blower can be quite inefficient and costly to operate, because the oxygen generated per HP of blower is lower than other means.

For good aeration in biofloc, we recommend 15 to 17 mtr of AirOxi aeration tube for every HP of single stage ring blower

3. Two stage regenerative blower

- The two stage turbine or ring blower is a middle ground between root blower and single stage ring blower

- It has become popular lately, but still not as popular as the regular single stage blower.

- This blower range starts from 1 HP onwards and is also imported like the single stage blower.

- The construction material and design, and operating principle is the same as the ring blower. However there is an additional stage provided before the discharge of air, to increase the pressure of the output air.

- As a result, many of the short comings of the single stage blower are overcome in this, although it still remains light weight and handy, and noise is less than that in a root blower.

- The air flow is little less than the single stage blower of the same power rating, however it is at a substantial more pressure. As a result the loss in piping, and reduction of air flow due to water head is not as drastic.

- As compared to a loss of 50-60% in single stage blower, the two stage blower would see a reduction of only 30% or so.

- They are also about 20% more costly than single stage ring blowers

- However the loss in piping is higher than in a root blower due to air flow with water head, being less than that in root blower.

- This blower is recommended for aquaculture when the farm is

- Indoor, in tanks

- Water depth is upto 5 feet

- When the distance from blower mounting area to water body is not much

For good aeration in biofloc, we recommend 20 to 22 mtr of AirOxi aeration tube for every HP of two stage ring blower

4. Diaphragm Air Pump

- Diaphragm air pumps are one of the most silent air flow devices that provide air flow at reasonably high pressure.

- They are designed for small and big indoor aquarium tanks, and hence noiseless operation is their main benefit.

- They work with air stones as well as aeration tubes, and the flow of air is at a low velocity, hence bubbles stay in air longer than with other high pressure blowers.

- This gives a satisfactory performance initially for the first 2-3 months, in aquaculture tanks also.

- However to achieve silent performance with moderate pressure, they need to give out very little air – usually starting from 30 LPM and going upto 240 LPM

- In fact air pumps along with air stones are the only aeration device used in aquaculture that are specified in LPM – litres per minute. All other blowers and diffusers are specified in m3/ hour. When one converts the LPM to m3/hr, and compares it to other blowers, one can see the huge difference in air flow.

- Biofloc culture is mostly done for fish that take 6-8 months to grow to full size. So sometime halfway in the culture, many farmers feel that the aeration provided is not sufficient.

- Hence a diaphragm pump is largely suitable for initial trials and experiments in aquaculture, for small size fish and for limited tanks, especially in urban areas where silent operation is necessary and power availability is less, and when individual tanks with less bio mass are to be aerated.

- The pump is also useful when aeration tube is to be cut into small pieces and distributed across the tank

For good aeration in biofloc through air pump, we recommend that you calculate 30 LPM as airflow of AirOxi aeration tube and according to the pump rating decide on the total meters of tube. So a 120 LPM air pump will support 4 meters of AirOxi aeration tube.

To help you summarize these details, a short table is given below, with some parameters mentioned against them. These are all mentioned relative to each other

Which blower is suitable for Bio floc and other aquaculture aeration

| Parameter | Twin lobe Root Blower | Two stage turbine blower | Single stage turbine blower | Diaphragm Air Pump |

| Air flow against water head of 4-5 feet | Very good | Good | Poor | Good |

| Volume of air available for aeration | Very good | Good | Good | poor |

| Initial investment | High | Moderate | Moderate | Low |

| Maintenance | Low | Low | Low | Low |

| Durability with continuous operation | High | Moderate | Moderate | Low |

| Installation | Difficult | Easy | Easy | Easy |

| Noise | High | Moderate | Moderate | Very low |

| Loss of air pressure in piping | Low | Moderate | High | High |

| Distance air can travel at required pressure | Long | Moderate | Short | Very short |

| Area needed for installation | Large | Small | Small | Very small |

| Recommended upto water depth | 10-12 feet | 5 feet | 1.5 feet | 4 feet |

| Use with multiple tanks and ponds | Yes | Yes but few tanks | No | no |

| Centralized installation possible | Yes | No | No | no |

| Recommended for indoor or outdoor | Outdoor | Indoor and covered outdoor | Indoor and covered outdoor | Indoor |

| Total volume of aeration possible | High | Medium | Low | Very low |

| Stocking density supported | High | Medium | Low | Very low |

| Suggested use in aquaculture aeration | For small, medium and large ponds and farms of all types of production size | For small sized farms, with individual blowers for each pond or tank | For mini farms or for initial trial purpose in small farms or for hydroponics or for small scale production | For small tanks and small scale production |

| Types of production size | Small scale production | |||

| AirOxi aeration tubes supported at 4-5 feet depth | 25 mtr | 20 mtr | 15 mtr | Pump air flow rating divided by 30 |

| Approximate fish biomass supported (there are many variables to this, only a thumb rule is given here) | 1 HP = 4 ton of fish | 1 HP = 3 ton of fish | 1 HP = 2 ton of fish | 120 LPM = 250 Kg of fish |

WhatsApp us

WhatsApp us

Leave A Comment